|

How to work

out the minimum resistor value that can safely be used:

To

establish the minimum resistor value, Ohm's law can be used. This

relates the current through a resistor to the voltage across that

resistor and can be expressed as V/I=R with V=Voltage in Volts,

I=Current in Amps and R=Resistance in ohms.

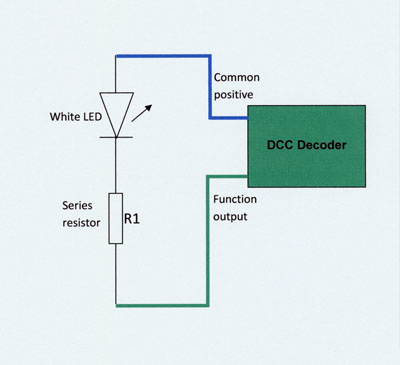

The

maximum current is part of the LED specification. Let's use a figure

of 15mA (=0.015Amps) for this example, which would be safe for most

modern LEDs (including 0805 chip types.)

The

voltage across the resistor can be estimated as the decoder output

voltage minus the forward voltage drop across the LED when it is on.

The voltage at the output of most DCC decoders is approximately 14

Volts. The forward voltage drop across the LED can be found in the

specification. For a white LED this is approximately 3 Volts. So the

voltage across the resistor will be approximately 14 - 3 = 11 Volts.

So

using Ohms law, with a Current of 0.015 Amps and a voltage of 11

Volts, V/I=R, so R=11/0.015 = 733

ohms.

Moving to the next highest standard value of resistor, a value of

820 ohms or higher can safely be used.

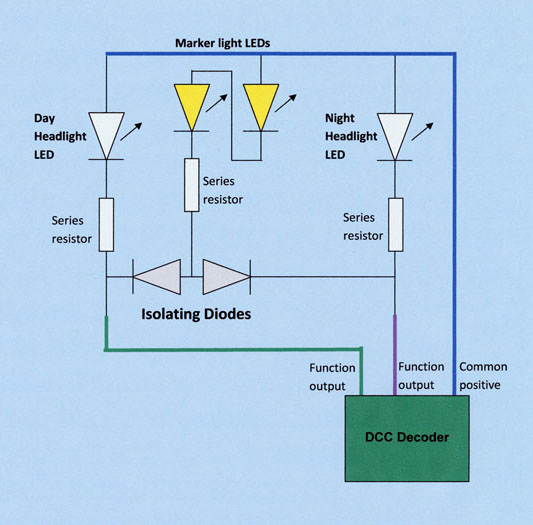

I

usually use around 2k7 for headlights, 10k for rear lights and

hazard lights and as much as 47k for directly viewed front marker

lights.

The

table below shows the forward current drawn by different colour LEDs

with some typical series resistor values when operating from a 14

Volt DCC output.

|

Colour |

Typical Application |

Single LED

Current |

2 Series

LEDs Current |

Series

Resistor Value |

|

White |

Very Bright

Head Light |

11 mA |

- |

1k |

|

White |

Normal Head

Light |

4 mA |

- |

2k7 |

|

Red |

Rear Light |

1.2 mA |

1 mA |

10k |

|

Warm White |

Front Marker

Light |

0.23 mA |

0.17 mA |

47k |

|

Amber |

DMU door

Warning Light |

1.2mA |

1 mA |

10k |

The best way to identify the optimum resistor value for a

specific application, is to equip yourself with a range of these

low cost components and to try a few values, homing in on the

effect you prefer.

|