|

First, the

Headlights:

Two

issues reduce the intensity of the headlights: a) Inverse square law

loss due to the distance of the source LED from the light pipe and

b) Losses within the light pipe.

The

plan is therefore to truncate the headlight light pipes and bond a new LED with

transparent glue directly to the new end of the shortened light

pipes. If this is not successful, plan B is to remove the remaining

light pipe from the lens and to glue the LED directly to the rear of

the lens..... although this will be trickier mechanically.

The

procedure is shown in the sequence of photos below:

|

Showing the light

pipe windows in front of the cab moulding |

Showing the light

pipe assembly with the cab removed |

|

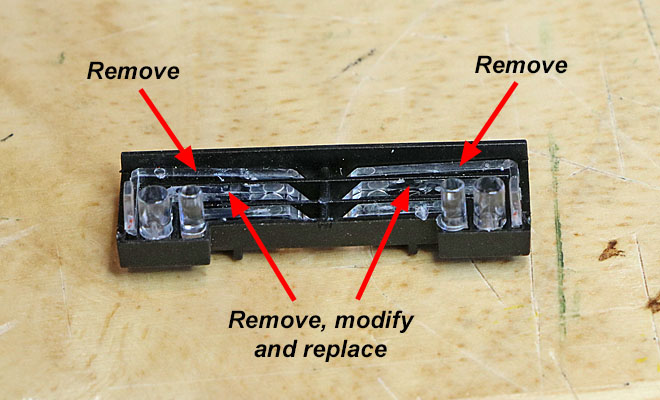

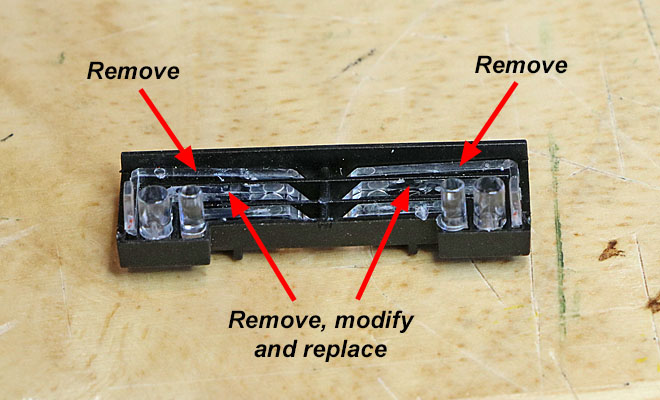

Extracting the

light pipe assembly from the body moulding

|

Proposed light

pipe assembly modifications |

Showing a headlight lens

with just the short vertical section of light pipe still attached. The light

pipe was cut using a Stanley knife.

A pre-wired "sunny white"

DCC Concepts Nano-LED is bonded (beaming into) to the exposed end of the

remaining light pipe.

(The lens is held in a

lump of Blu Tack, while the glue dries.)

After the glue has set,

the LED is fired up using a suitable series resistor and DC power supply.

Light leaking out of the

sides of the LED is minimised by careful application of black enamel paint.

Repeating for the other

side. (This LED works fine but has a conspicuous solder blob, which might

explain why the pack contained 7 LEDs rather than the specified 6?)

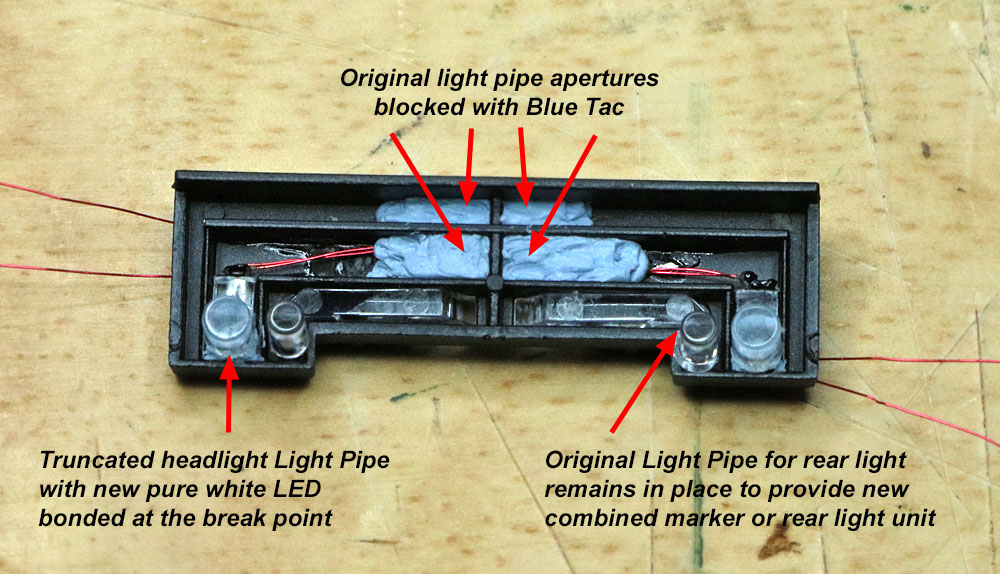

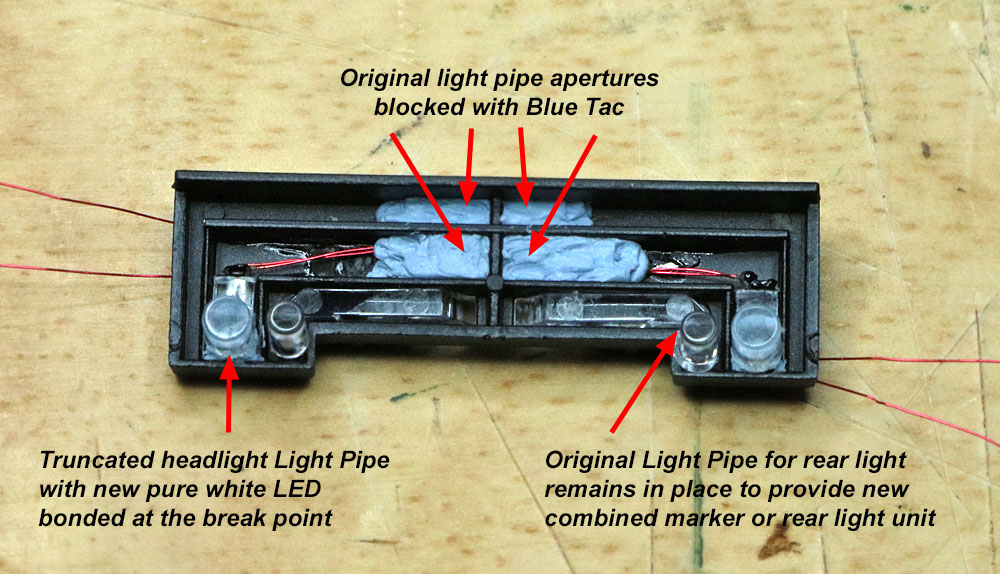

Showing the re-assembled

light pipe enclosure. The LED wires are routed through the old headlight

light pipe apertures in the rear of the enclosure.

Blu Tack is used to block the

now unused light pipe apertures and also to provide temporary support to the

rear of the headlight lenses.

In this photo, the light pipe

enclosures have been re-fitted and cab mouldings re-installed at both ends

of the locomotive.

The series resistors for each

new headlight LED are glued to the inner side of the locomotive roof, and

the interconnecting wires have been added.

|

Next,

converting the original rearlights into dual rearlight / marker

lights:

The

original warm white headlight and marker light chip LEDs are removed

from each of the original lighting boards. A thin plasticard strip

is glued to the PCB just above the original rear light chip LEDs.

Pure white pre-wired chip LEDs are glued to the plasticard

insulator, as close as I dare to the original rear light LEDs. The

new chip LED wires are soldered to the pads of the original marker

lights at the top of the PCB (being careful to get the polarity

correct.)

With

the headlight LEDs now removed from the small lighting boards, there is no

longer any need to re-use the

plastic shroud moulding that was previously fitted over the LEDs, prevented light leakage between the

lamp lenses.

|

Front view of modified

small lighting board assembly

|

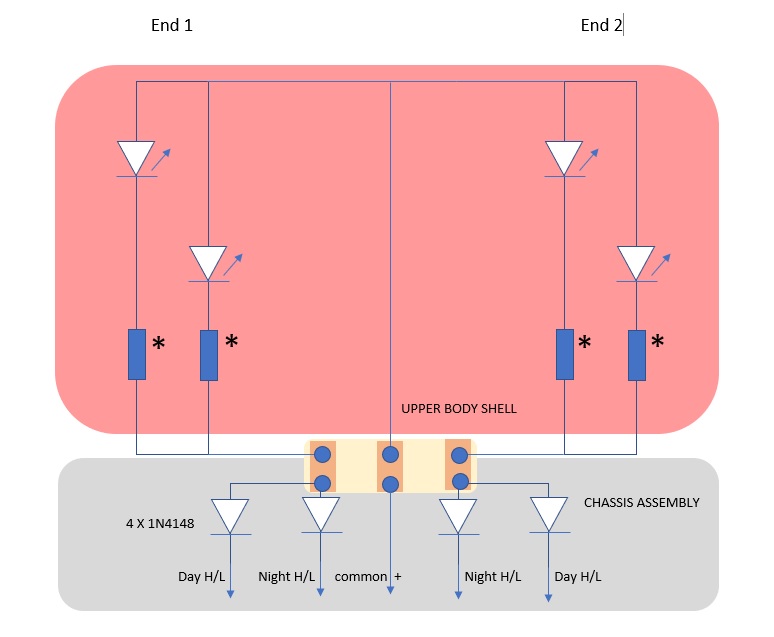

Electrical

connections between the new headlights in the upper body shell and

the chassis assembly:

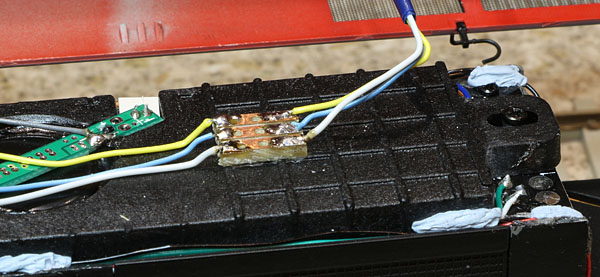

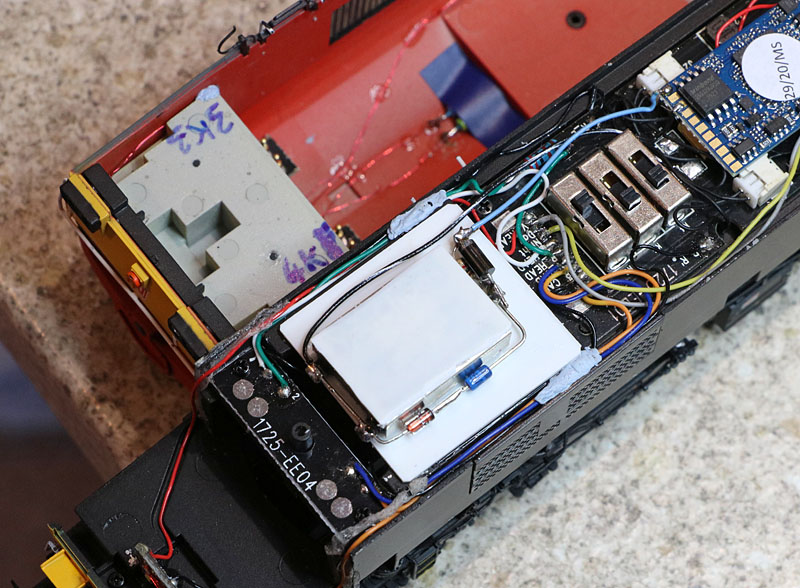

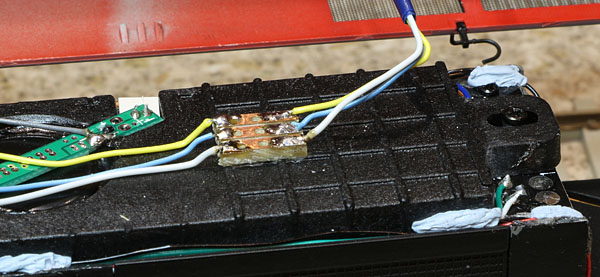

Three

wired connections are made to a small section of solder strip, glued

to the top of the EM2 loudspeaker. The wire length is contrived to

lay along the top of the chassis assembly when the upper body has

been re-fitted.

|

Close-up of the solder

strip

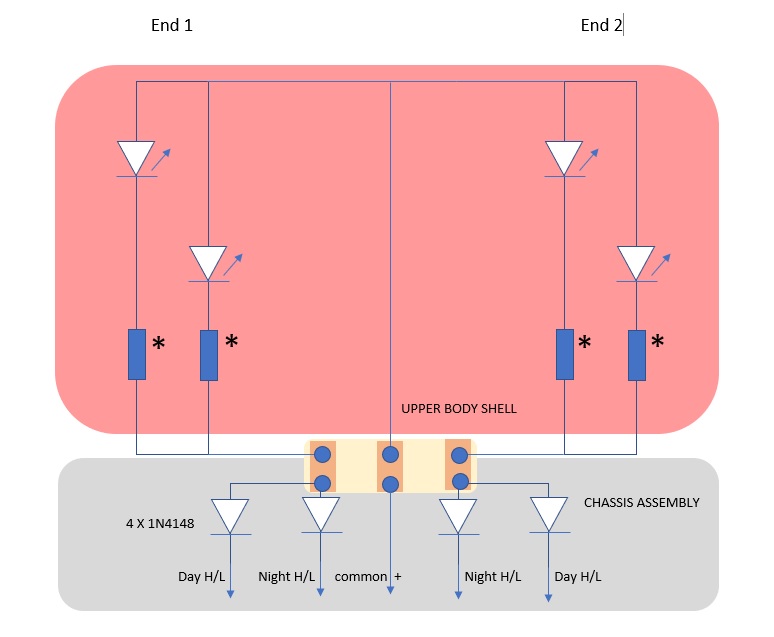

Headlight LEDs electrical

circuit..... Resistors marked *

are between 2k2 and 4k7, selected for equal brightness.

|

LokSound V5

settings for main beam and dipped beam headlights intensity:

The

main beam function output level CV is set for maximum intensity (31) and the

dipped beam CV, to 6. The views below show the head-on results,

illustrating that the headlights are significantly brighter than in

Hatton's original arrangement.

The

new marker lights and original rear light LEDs successfully share

the new dual purpose marker / rearlight lenses. (The original

rectangular marker light apertures were subsequently filled and

painted black.)

|

Dipped Headlights |

Main Beam

headlights |

|

Rear Lights |

|

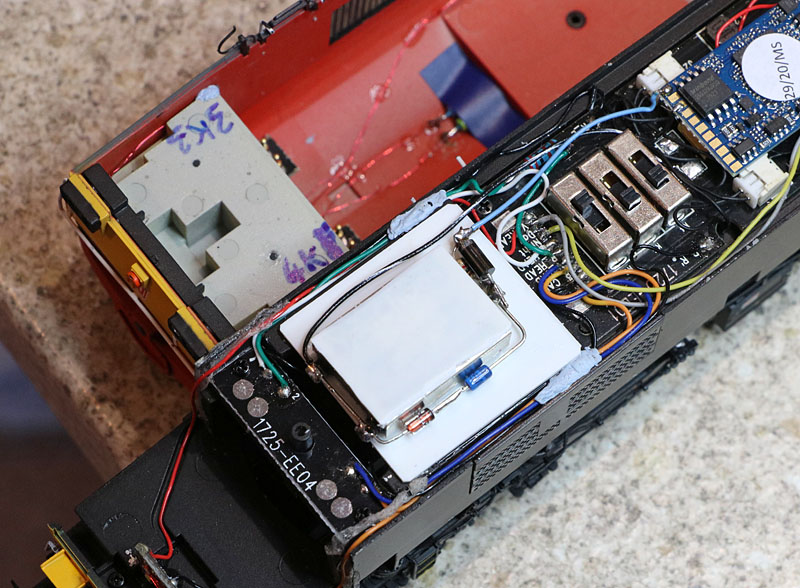

Stay Alive

Super-cap:

To

improve reliability, I've added a 6800uF AVX supercap, sourced from

YouChoos DCC. These devices are rated at 15 volts maximum, which is

often exceeded on DCC layouts...... So to be safe, I always fit a

series resistor and zener diode to prevent the charging voltage

exceeding 15Volts. Having just used up my supply of 14 volt 500mW

zener diodes, this time I found some low cost 5V6 and 9V1 zeners on

Amazon. When connected in series, a pair of these limit the voltage

seen by the supercap to typically around 14.7 Volts, which works

very well. I glued some thin plasticard to the top of the supercap

just in case it comes into contact with the roof mounted components.

|

Supercap circuit glued

to a plasticard deck, bonded to the chassis block. Electrical

connections

are made to the common

positive and ground solder tabs on the decoder.

|

A decision on

a possible livery update:

The

red bodywork colour is painted. It is not the colour of the

plastic moulding. I'm not confident about a clean removal of the original DB Schenker logos without collateral damage to the red paintwork,

without an appropriate touch-up paint supply, so despite obtaining

DB transfers for the job, I've decided to leave the current DB

Schenker finish in place.

|

The finished locomotive