|

Lighting

Control:

I have now changed the lighting control on all the 66s from Bif's

original concept, to instead provide independent lighting control at each

end of the locomotives. I found this simplified consist operation of

the two DRS 66s I use on military nuclear flask

trains etc. It then made sense to apply the same modifications to the

other Hattons 66s, to maintain a common approach.

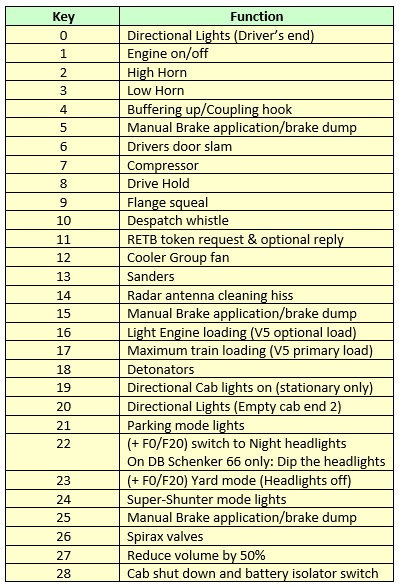

Key

F0 activates directional lighting at the driver's end. Key F20 does

the same at the other end. Key F22 changes headlights from day to

night (except for the DB loco, where it switches headlights from

main beam to dipped.) Key F23 disables headlights for in-yard work.

With

other lighting keys off, Key F21 activates parking rears at each end

and Key F24 alternately flashes marker and rear lights at both ends

as warning lights when shunting.

Key

F19 activates the forward cab light in the direction of travel but

only when the locomotive is stationary.

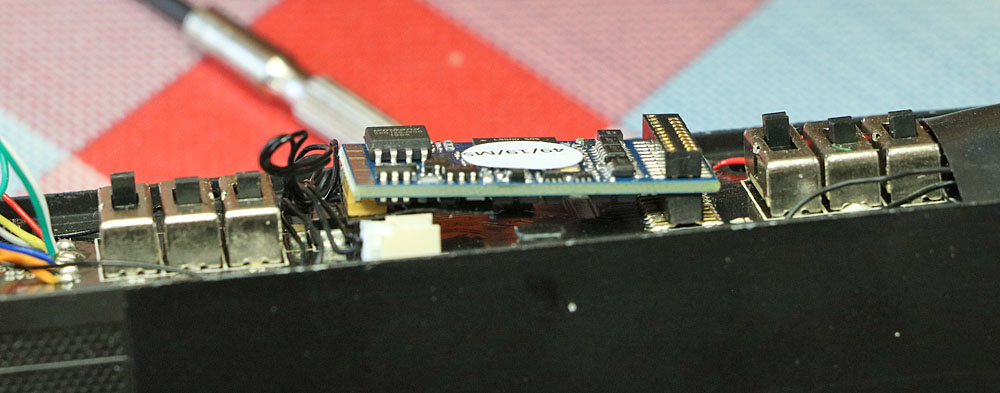

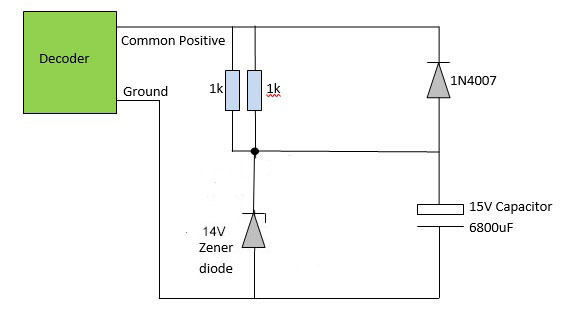

The LokSound V5 MKL has enough full power function outputs to drive

rears, markers, day & night headlights and cab lights independently

at both ends of the locomotive. This means that variations on Biff's

original lighting control theme can be largely achieved using a LokProgrammer

to change the function mapping.

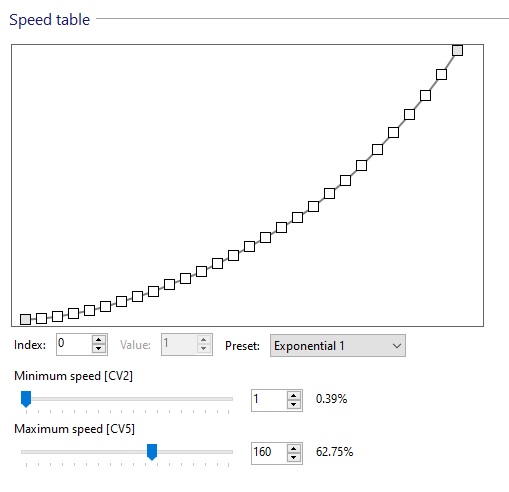

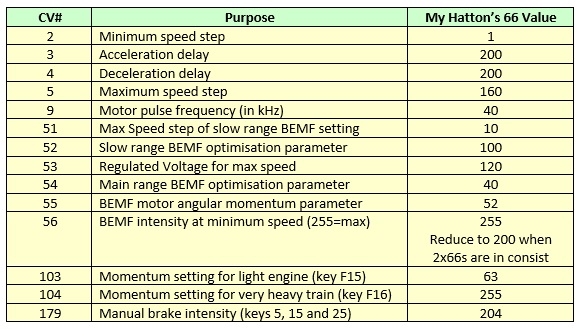

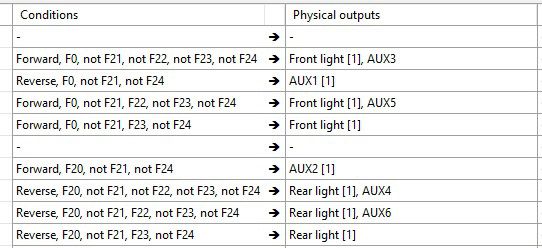

Table indicates the

LokSound V5 MKL decoder function outputs used for each lighting function

Function

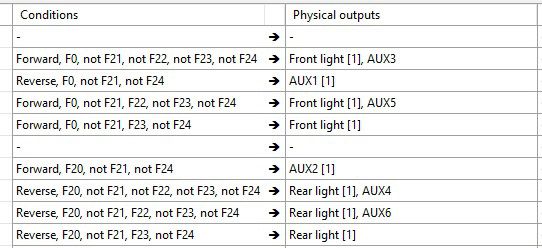

Mapping update for the Lighting:

GBRF,

Freightliner and DRS locos are driven with the short cab / roof fan

vent end forward.

The

lighting sections of the function mapping for these locomotives are reproduced below as

they appear on the LokProgrammer screen.

Colas

and DB Schenker locos are driven with the long cab / roof exhaust

end forward. Mapping for these locos is as follows:

(The

direction control of these two locos is reversed via CV21.)

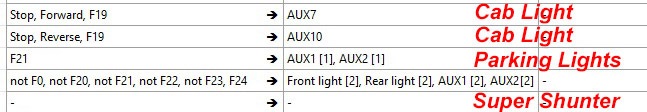

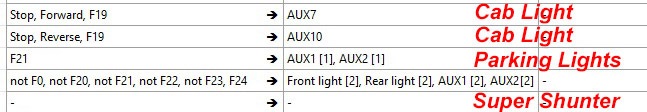

Cab

lights, parking lights and super-shunter lights are common to all

locos. Mapping of these is as follows:

(The

mode [2] front and rear plus Aux1 and Aux2 light configuration outputs flash alternate markers and rear

lights.)

Dimming the

upper marker lights:

As

received, the upper marker lights are typically brighter than the

headlights on all the Hattons 66s. To

reduce the intensity of these lights, an additional

series resistor (value circa 39k) has been added at both ends of

the locomotive.

Hatton's

66 variants with large headlights:

e.g.

My Freightliner and Colas 66s..... An

unfortunate design error resulted in only a single lower marker

light coming on at any time, together with the headlight on the

opposite side. Fixes for this issue

are described in some detail in another of my web pages. (See site menu).

Large headlight

Freightliner 66.

Specials:

My DB

Schenker 66 has modified headlights with corresponding changes to

the markers, to simulate the new all LED Wipac lighting modules on

some DB locomotives. These mods are described in detail on another

dedicated web page (see site menu).

DB Schenker 66 with

modified headlights.

|