|

Straight Out Of The Box: Good news! No obvious build issues or missing parts! In particular, no cosmetic problems on my example, GBRF number 66756 "Royal Corps of Signals". The level of detail was a big step-up from Bachmann's 66, which despite forming an industry standard for a considerable number of years, is now beginning to show its age. The Hatton's model is also considerably heavier. The only obvious visual omission was the lack of a miniature driver in the front cab. |

|

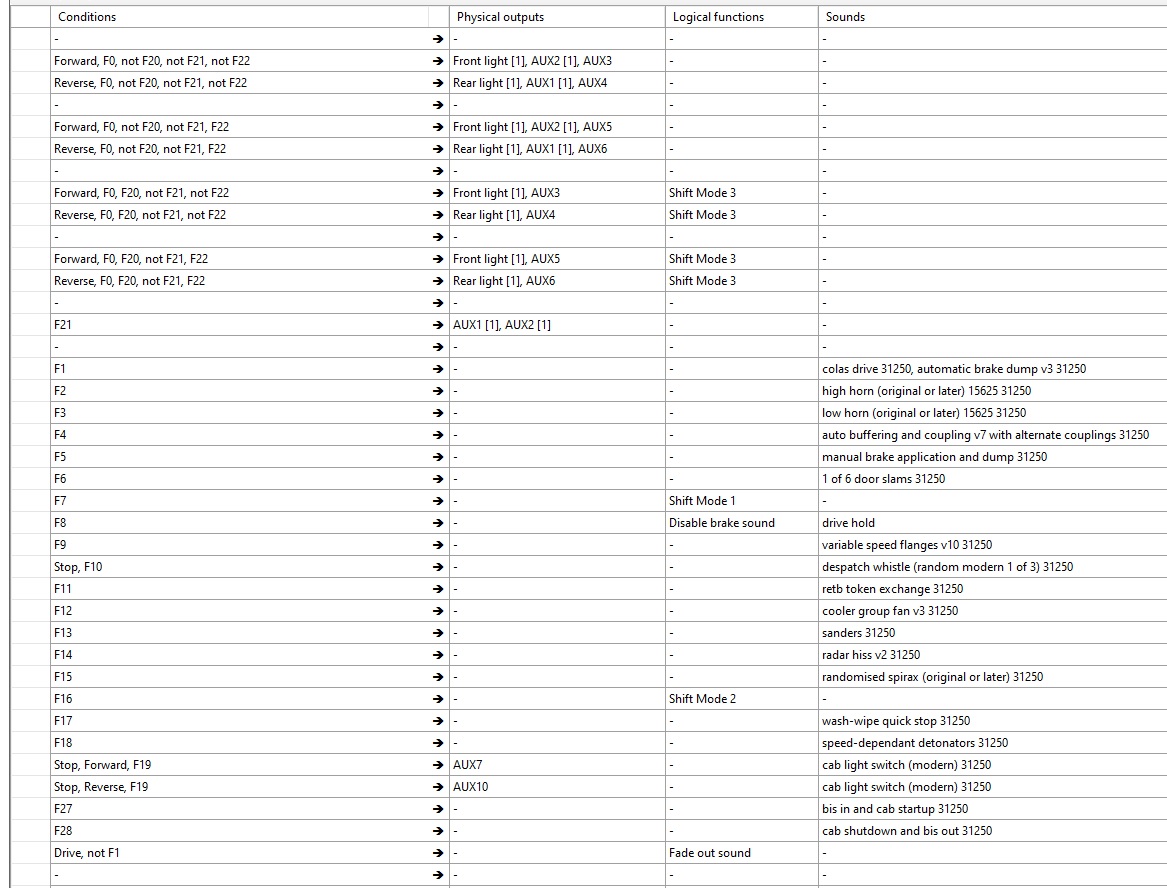

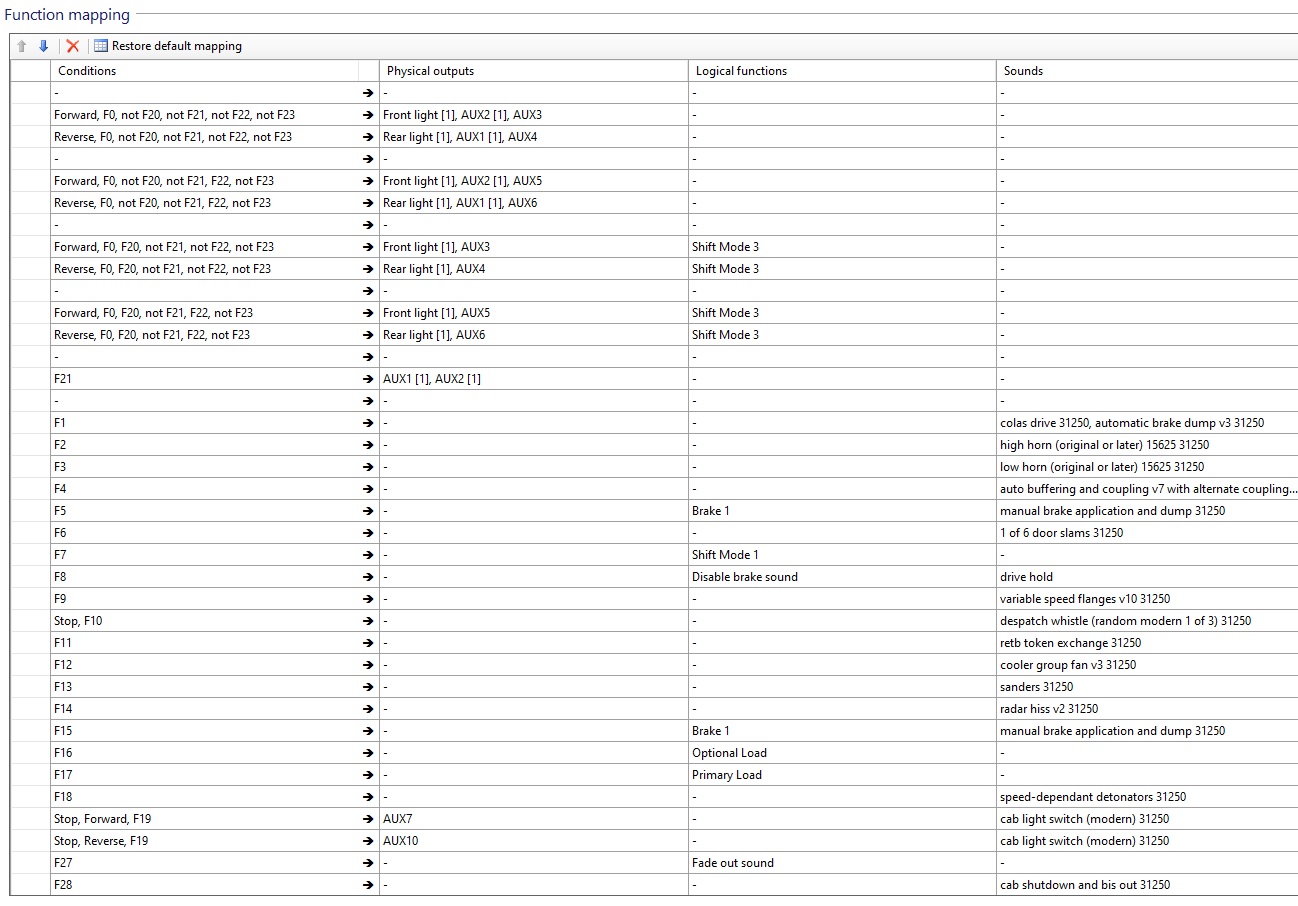

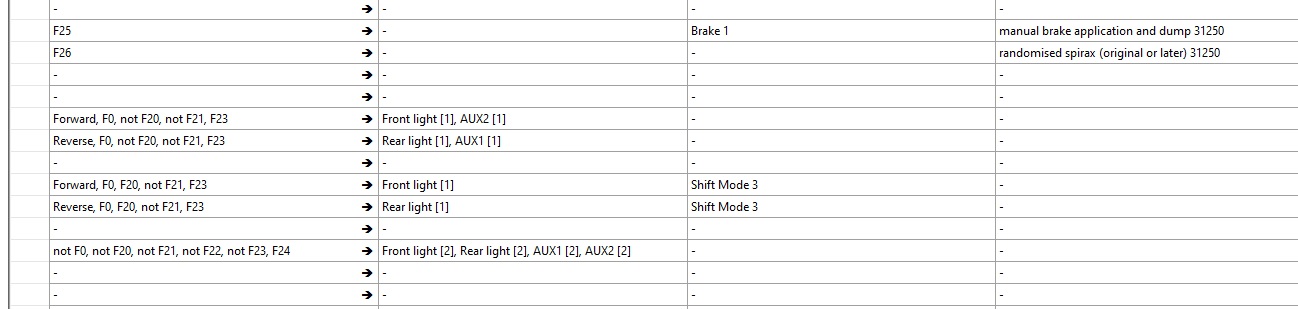

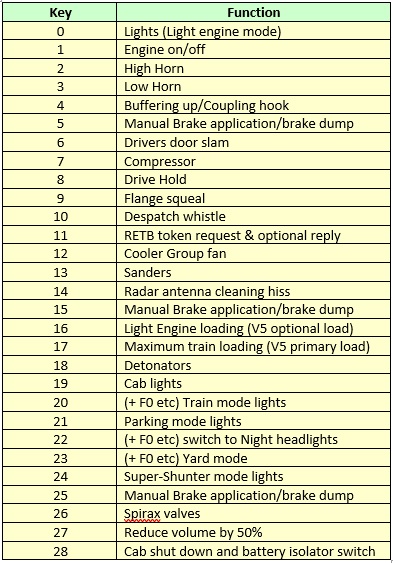

Initial DCC Testing: Firing up the sound for the first time produced some impressive bass content thanks to the big EM2 speaker. (Fortunately I'd remembered to wind down the master volume first.) However very slow speed movement was not as smooth as I had hoped. As speed was increased, although the motor behaviour improved, a distinct side to side wobble also became apparent. Lighting all worked as advertised, with (unlike Bachmann) all three marker lights operational. Day or night headlights, train end lights disable function plus a parking lights option were all in place. Also directional cab lights configured to extinguish during driving. However, the top front marker lights were disproportionately bright (brighter than the headlight from most angles.) Just like the real Class 66, the outer wheel bearing covers rotate with the wheel axles. (I can only see this feature by getting close to the locomotive with my reading glasses on.) Unfortunately, not so prototypically, the central bearing covers on each bogie, also move in and out from side to side when negotiating curved track. Although an interesting innovation, this feature has proved to form the models main Achilles heel, as becomes apparent further down this page....... So, although a really impressive model with excellent sound and very flexible lighting, there were quite a few issues to address before the loco joined the fleet. |