60529 Pearl Diver (Hattons photo).

|

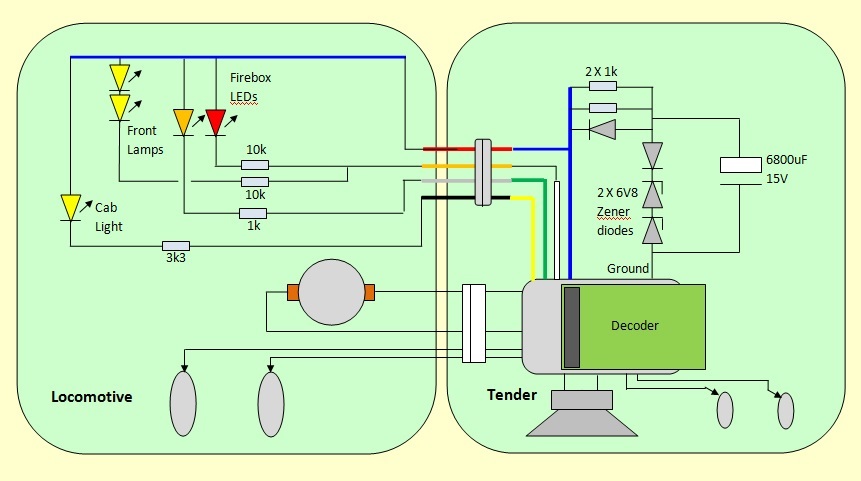

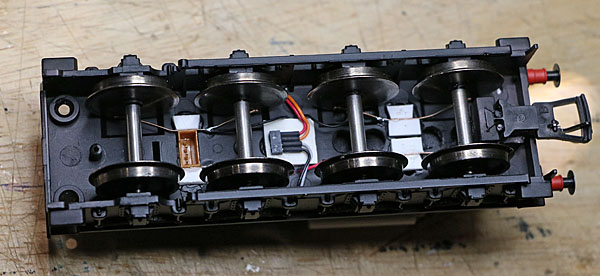

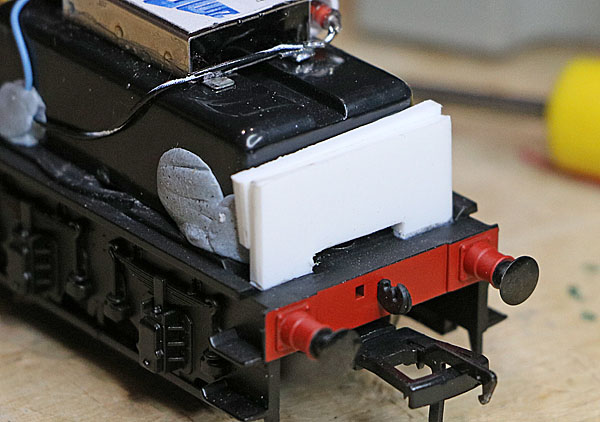

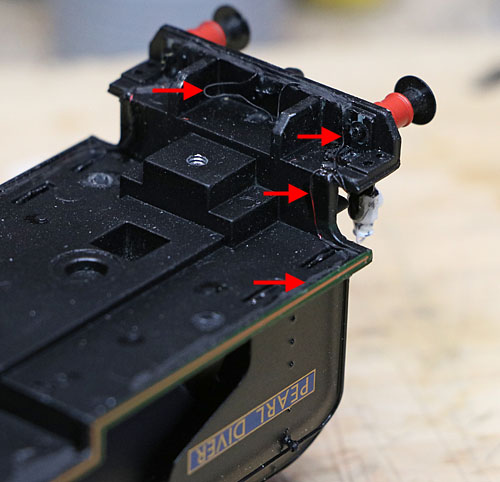

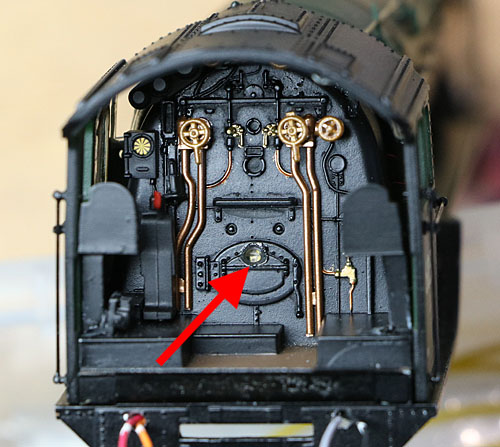

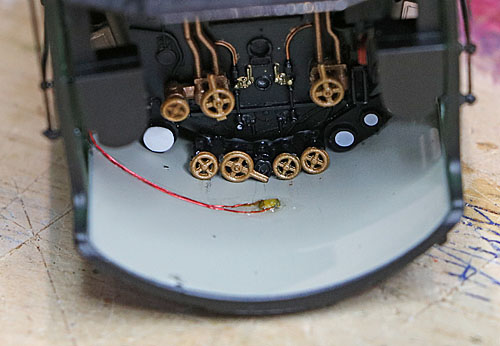

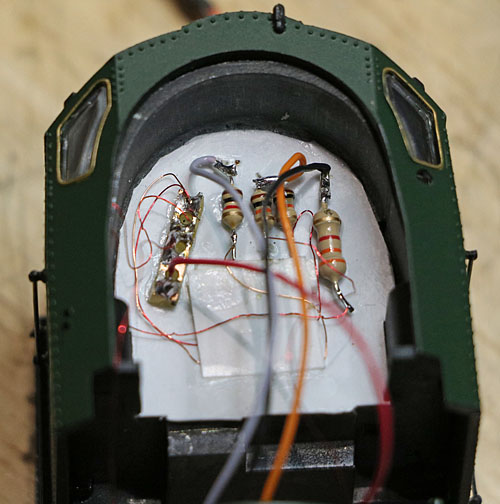

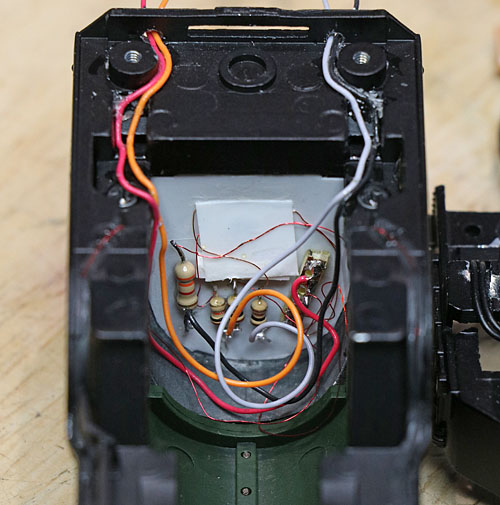

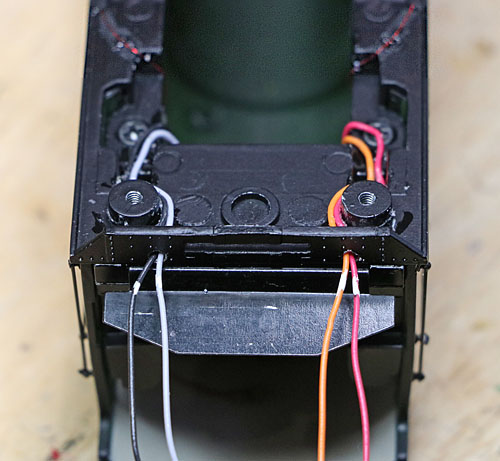

Likely scope of the update: South West Digital A3 LokSound V4, or Digitrains Zimo A3, whichever gives the best results...... Both exhibited similar motor control characteristics, but there was little doubt that the audio quality and behaviour of Paul Chetter's (aka Digitrains Active Drive) A3 is the best! Downward facing 20x40mm ESU 50334 speaker in its standard enclosure in the tender (with plastic material removed from the floor to improve the sound output). Twin DCC Concepts oil lamps mounted on the bottom outside brackets, plus fire box red and amber LEDs. Also, these locos had an electric cab light. (TMC micro connector back to the tender.) Stay alive capacitor in the form of a Zimo 6800uF super cap in the tender, with a zener diode protection circuit to keep its charge voltage within specification. Plus wheel contacts fitted to the tender (none fitted by Bachmann!!!). |

Another Hattons shot.

|

First impressions: Straight out of the box, the initial impression was good, with a familiar shape, good finish and crisp graphics. Looking more carefully, some minor issues became apparent: The wire hand rail on the right hand side of the boiler was bent away from the boiler in one section. (Remedied by careful straightening) There are minor signs of paint abrasion on the underside of the chassis and there are scratch marks on the underside of the left hand piston housing. (Fortunately neither are noticeable when the loco is mounted on the track.) A brief run using DC analogue control on a short track section suggested reasonably smooth motor performance. |