|

Background: My childhood memories of the A4s on the ECML are exclusively double Kylchap chimney variants with the original side valances removed. Unfortunately, all recent Hornby A4 releases have involved single chimney variants (except for Railroad Mallard models in blue with valences fitted). These just don't look the part to me. It is still possible to find Brunswick green BR A4s, but rarity seems to have pushed the purchase cost beyond what I was prepared to pay....... However, Olivias Trains in Sheffield had stock of an A4 in the required configuration, in wartime black livery. A discounted price tipped the balance, so with a little imagination, the plan is to run the model, hauling troop trains, between our warwell tank trains, as part of our WW2 period sequence, on the Histon village layout. |

|

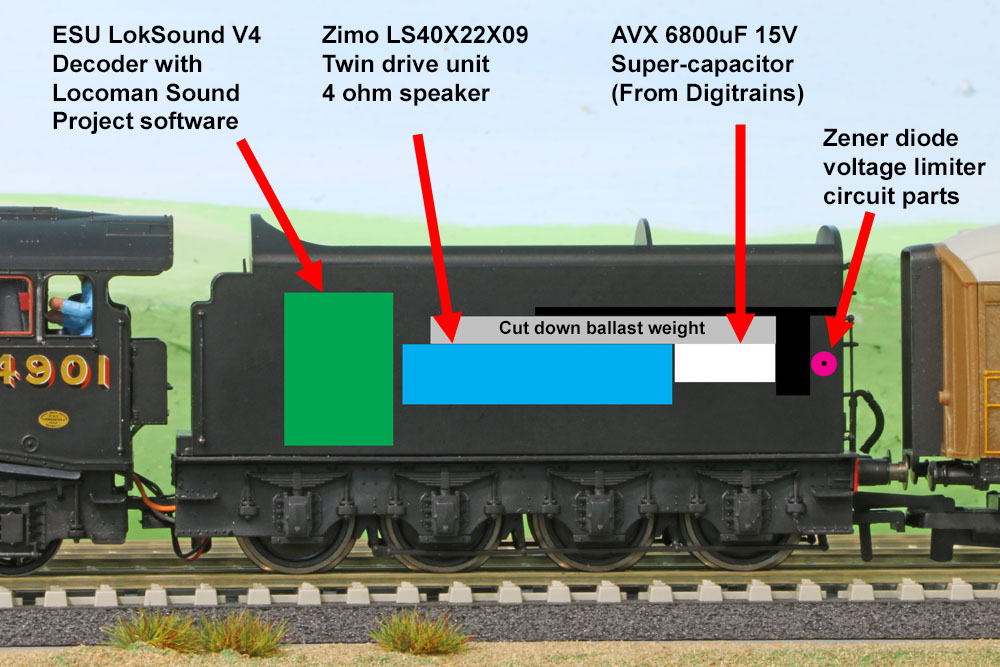

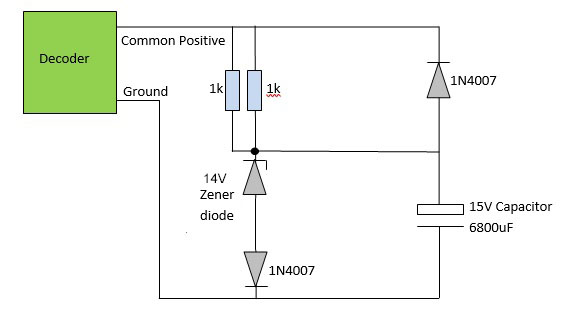

DCC Configuration: The A4 gives me the opportunity to try a new source of steam loco sound system. I plan to install an ESU LokSound V4 equipped with "Locoman" sound project software. Although this model has the well regarded current Hornby body mouldings and running gear, it is early enough to have an 8 pin DCC socket within the loco body. The tender also has wheel contacts, but relies on the old Hornby coaxial connector between loco and tender to link these to the DCC socket. I propose to re-wire the motor and loco wheel contacts back to the tender, where I will fit the decoder, speaker and a 6800uF stay alive capacitor with an over-voltage protection circuit. Much to my surprise, I received a phone call from Locoman, a few hours after placing the decoder order, to confirm the package would be in the post, special delivery for the following day and requesting my constructive feedback on how I find the sound system behaves. Good to see such an enthusiastic response! |

|

DC Testing: The locomotive is a smooth runner in DC configuration, straight out of the box. Slow speed running is quite reasonable for a Hornby steam loco under DC control. Using my bench power supply which provides pure DC, the motion is virtually silent at slow speed. So I'm not expecting too much of a drama when I try to optimise the DCC motor control. |